Company

Since its foundation in 1994...

...URETEC s.r.l. is a company specialized in the processing of polyurethane materials for the realization of elements necessary for many different industrial applications.

Initially established itself as manufacturer of components, such as cleaners and screens, for the machinery of the paper and mining industries, now URETEC produces a very wide range of articles, oriented to all kind of industry that require, for their machines’ components, materials particularly resistant to abrasion or dynamic stresses such as polyurethane.

Through the years, URETEC s.r.l. has acquired a greater and complete productive ability and can offer its customers a wide range of services ranging from design to the development of customized solutions, able to meet the most different needs. Nowadays, the particular experience consolidated in these years makes URETEC s.r.l. reference point in the manufacture of products for the screening of aggregates as well as for a wide range of other technical articles.

Lorem ipsum dolor sit amet consectetur

Lorem ipsum dolor sit amet consectetur

Materials

URETEC s.r.l. has been manufacturing polyurethane components for the industry since 1994. The materials used come from different chemical species and are available with a wide range of hardness, thus they can be used in various industrial sectors.

Amongst the main characteristics of polyurethane, you have:

• a high level of resistance to abrasion;

• a high level of resistance to impact and compression resistance;

• the high elasticity;

• excellent resistance to oils, solvents and hydrolysis.

In order to meet the different needs of the market, URETEC has been equipped with different products, each with its own peculiarities; so that it can choose each time the most suitable material for the specific application. In principle, the materials used belong to two groups: Ether-based MDI and ester-based MDI.

Ether-based MDI

In humid and warm environments, ether-based MDI systems are necessary to prevent damage caused by hydrolysis or contact with acids and bases. This product is suitable for applications such as hydro cyclones, snow blades, screens and seals, thanks to the high adaptability of the material at low temperatures and a low level of compression.

The key properties of ether-based MDI are:

• a high level of resistance to abrasion;

• a high resilience;

• excellent resistance to hydrolysis;

• a very good level of resistance to micro-organisms.

Ester-based MDI

Ester-based MDI systems offer a greater resistance to abrasion and tear as well as a high resistance to hydrocarbons, oils and solvents. This system is the ideal choice for applications such as screening nets, scrapers and plates.

The key properties of ester-based MDI are:

• excellent abrasion and tear resistance;

• good chemical resistance;

• excellent dynamic properties.

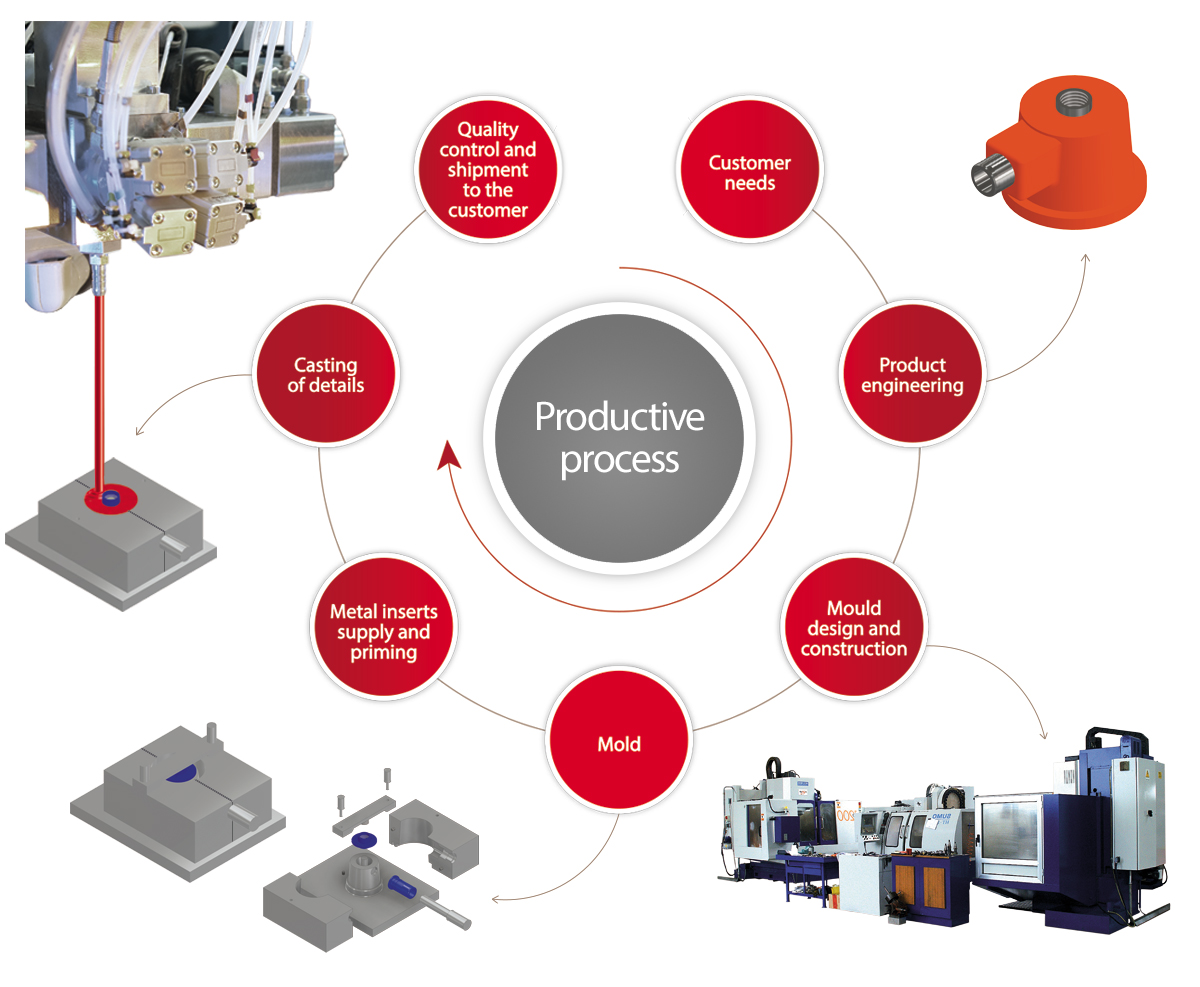

Productive Process

Through a precise procedure, which begins with our customer request for a specific application, in a few hours our technicians develop the best solution by relating all the factors at stake: use, environmental conditions, the necessary geometry, the feasibility conceived as the right balance between costs and the required result. We design the workpiece, create the mould in our mechanical department, identify the most suitable polyurethane material that will be poured in the liquid state and then reticular to reach the hardness required ranging from 55 Sha to 70 Shd. The original idea of our customer is thus translated into reality through ambitious solutions resulting from our experience.